Product description

Agitated Nutsche Filter Operation

- The slurry is fed from the reactor into the top compartment from where filtrate passes into the lower chamber en route to the receiver. Solids are deposited on the filtering media in the top compartment and take the shape of a cake of a uniform thickness.

- The agitator pushes the solid content in the slurry upwards by keeping it under suspension till the maximum possible filtrate passes through the filter bed. This reduces time and increases productivity. It then seals the cracks in the cake, which develop after most of the filtrate has passed through, by smoothening the top surface of the cake. It also squeezes out some of the moisture in the cake by slightly pressing the cake uniformly with the help of specially designed blades.

- After the initial solvent/mother liquor has been separated, sometimes it is necessary to wash the cake. The Agitator has been designed in such a way that after adding wash liquor on the cake, the entire cake can be re-slurred and agitated so that all the particles forming the cake can be exposed to wash liquor and be thoroughly washed. This improves the quality of the finished products.

- After washing and removal of wash liquor, the cake can be discharged through a quick opening side discharge valve, by rotating and lowering the agitator in the discharge direction. All process control by means of the control panel.

Agitated Filter Feature

The process works as a completely closed system, eliminating any possibility of atmospheric pollution from toxic fumes / obnoxious smells generated from the slurry.

- Maximum solvent recovery is possible.

- Explosion or fire hazard on account of spillage is eliminated.

- Less Manpower requires. All operations can be handled by a single unskilled person with little training.

- Very effective washing of cake due to re-slurring resulting in thorough particulate Washing and reduces the number of washes, and volume of wash liquor.

- Possibility of doing reaction filtration, washing, and distillation in the same equipment. In some cases, drying operations can also be carried out in the same equipment. Heat transfer surface can be provided by means of a jacket or limpet coils on the vessel walls. Indirect heating can be provided on the filter base and agitator.

Available in special construction for sterile applications with a high standard of particulate purity.

Nutsche Filter Material of Construction

- Carbon Steel

- Stainless Steel

- Super Stainless Steels

NOTE

Sizing, selection of configuration, M.O.C’s, methodology of filtration, etc. are based on material characteristics.

Agitated Nutsche Filter Option

- Pressure-Cum-Vacuum filter.

- Bottom detachable type for ease of cleaning/ cloth fixing.

- Hydraulic Shaft lift.

- Hydraulic discharge valve.

- cGMP Models

- Filter-Cum- Dryer for drying wet cakes.

- Different stirrer designs based on the physical characteristics of materials.

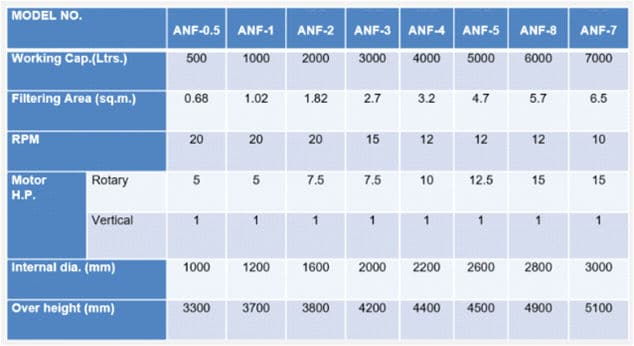

Capacity and Model

We Are the Leading manufacturer and Exporter of Agitated Nutsche Filter in Ahmedabad, Gujarat, India